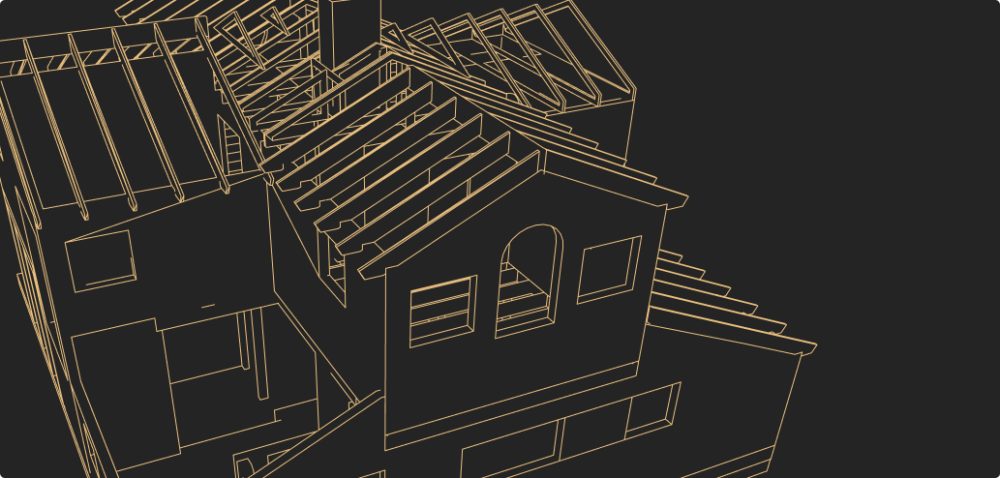

Our Process

Our diverse team of designers, engineers, managers and installers have an integrated approach to the execution of your project that is unique in the sector.

Our diverse team of designers, engineers, managers and installers have an integrated approach to the execution of your project that is unique in the sector.

Our shop drawings are detailed to an accuracy of 1/64th of an inch, and our layout team are accurate to within 1/32nd.

Regardless of the type or species of wood, we carefully inspect each and every piece of your home, and orient it in the frame to suit considerations like strength, load and beauty.

This accuracy is guaranteed by a quality control process that sees each piece independently checked by the craftsman responsible for cutting the piece.

Once all the timbers have been cut it is time to pre fit the frame elements in the shop.

Each section of the frame is fit together in our shop, and assembled to ensure that the finished frame is correct in all regards, the dimensions are as indicated in the plans and each joint is tight and beautiful.

When all elements have been fit, they are sanded or adzed, and in some instances finished with a product of the clients specification.

When the site is developed to the point where they are ready to install and enclose the timber frame it is trucked to site and raised.

The raising of a frame is a special privilege for everyone who’s worked to create this one of a kind structure.

We are proud to say that our crew enjoys their craft, and thrive within the team attitude that building such beautiful cooperative projects requires.

Our craftsmen take their responsibilities seriously, and take great pride in every project.

While each timber build is customized, these mock ups reflect the package that can be expected when selecting us as your Design Development partner.