Nail Laminated Timber

What is it?

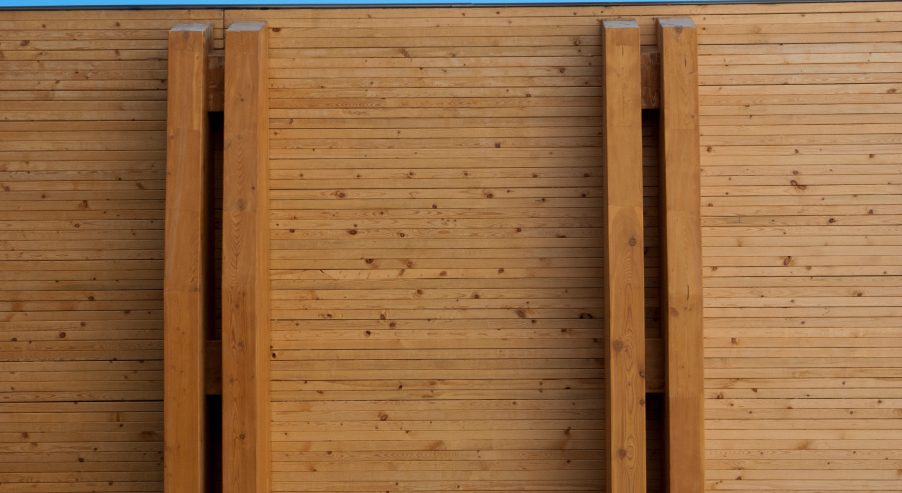

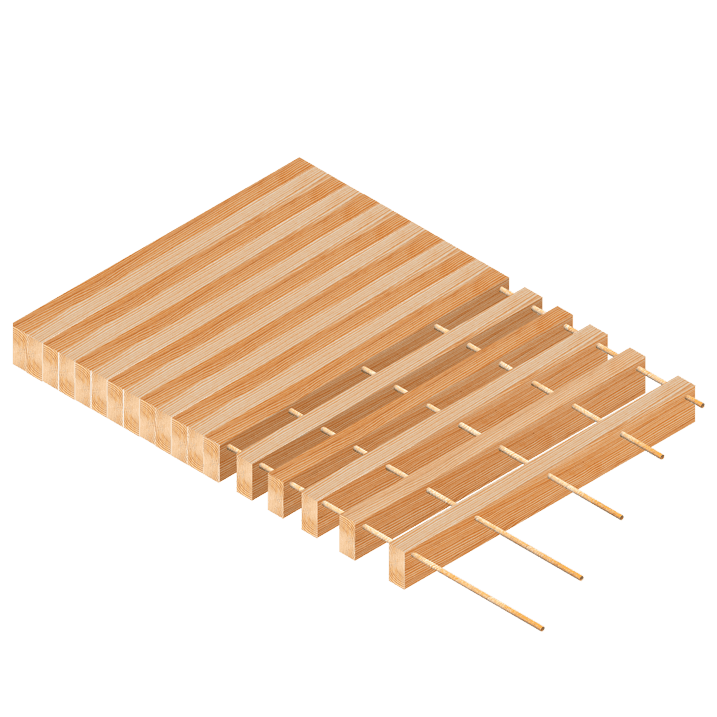

Nail Laminated Timber, commonly known as NLT, is a fabricated mass timber product which is created by stacking dimensional lumber on edge and mechanically nailing or screwing the laminations together in an engineered pattern to create panels. When manufacturing NLT, plywood sheathing is commonly added to the top side of the panel to support structural strength.

Originating as a common element used in various construction applications dating back to the turn of the century, NLT was historically laminated in place by hand. With the advancement of mechanical technology, NLT has found a resurgence in its ability to be fabricated in large quantities, utilizing an environmentally-friendly, renewable resource.

NLT is available in thicknesses which vary from 3.5” to 11.25”, and upwards of 48’ in length and can be fabricated from various species including spruce and douglas fir. Lumber grades become important when considering the design element of the NLT. When left exposed as a design feature lumber grading becomes an important consideration. NLT’s are available in Select Structural, No.1 and No.2 grades, with the higher appearance grade offering the most aesthetically pleasing element.

Construction Applications

Traditionally, NLT was used in the construction of timber bridges, as well as the floor element of industrial and commercial settings. In recent years, designers have opted to specify NLT as an option for executing complicated architectural features and designs. Generally used as a panel product for walls, roofs or floors, NLT can also be extended to provide aesthetically pleasing design features in both residential and commercial applications.

Benefits

The vertical alignment of the lamina produces an unmatched efficient panel, which can be used to create slab panels that support a range of design and structural needs based on design specifications.

The more cost-effective option over CLT, NLT offers both exposed or concealed applications as well as overall greater acoustic performance. Compared to CLT, NLT is a superior product which provides structural advantages, lower costs and quicker procurement times. When combined with Glulam, NLT panels are more structurally efficient than CLT panels due to the strength of the wood fibres being laid in the same direction. NLT is does not require additional fire-proofing and in the event of a fire the timbers and panels would char, forming a protective layer and allowing the wood to remain structurally viable.

Additionally, NLT offers a more sustainable option to the widely used steel and concrete construction, while providing a more cost-effective, structurally sound product that limits the carbon footprint.